2-Surface Plating:

(1)Ultrasonic cleaning;

(2)Anodizing;

(3)Powder Coating;

(4)Tinning Plated

3-OEM/ODM:Accepted,need your drawing

4-Free Samples:10-50pcs is allowed

5-Lead Time:Samples 10-20days,Orders 7-10days(including the tooling/die production)

6-Production Capacity:50,000,000 pcs/month

7-Packing:Inner plastic bag,Outer carton/pallet

8-Payment Item:T/T,L/C by USD/EUR/RMB

9-Quality Standard:ISO9000,IATF16949,RoHS,REACH

10-Application:

6061 Aluminum Alloy Stamping Parts features:

1-Good formability, weldability and electroplating

2-High strength and high toughness

3-Good usability and excellent interface characteristics

4-Easy to process and easy to coat

5-Good corrosion resistance and oxidation resistance

6-easy to polish, easy to color film, excellent oxidation effect

The main purpose of 6061 Aluminum Stamping:

6061 aluminum rod and tape are commonly used in aviation fixtures, trucks, tower buildings, boats, pipelines and other applications where strength, weldability and corrosion resistance are required. Such as: aircraft parts, gears and shafts, fuse parts, instrument shafts and gears, missile parts, jump valve parts, turbines, keys, aircraft, aerospace and defense applications.

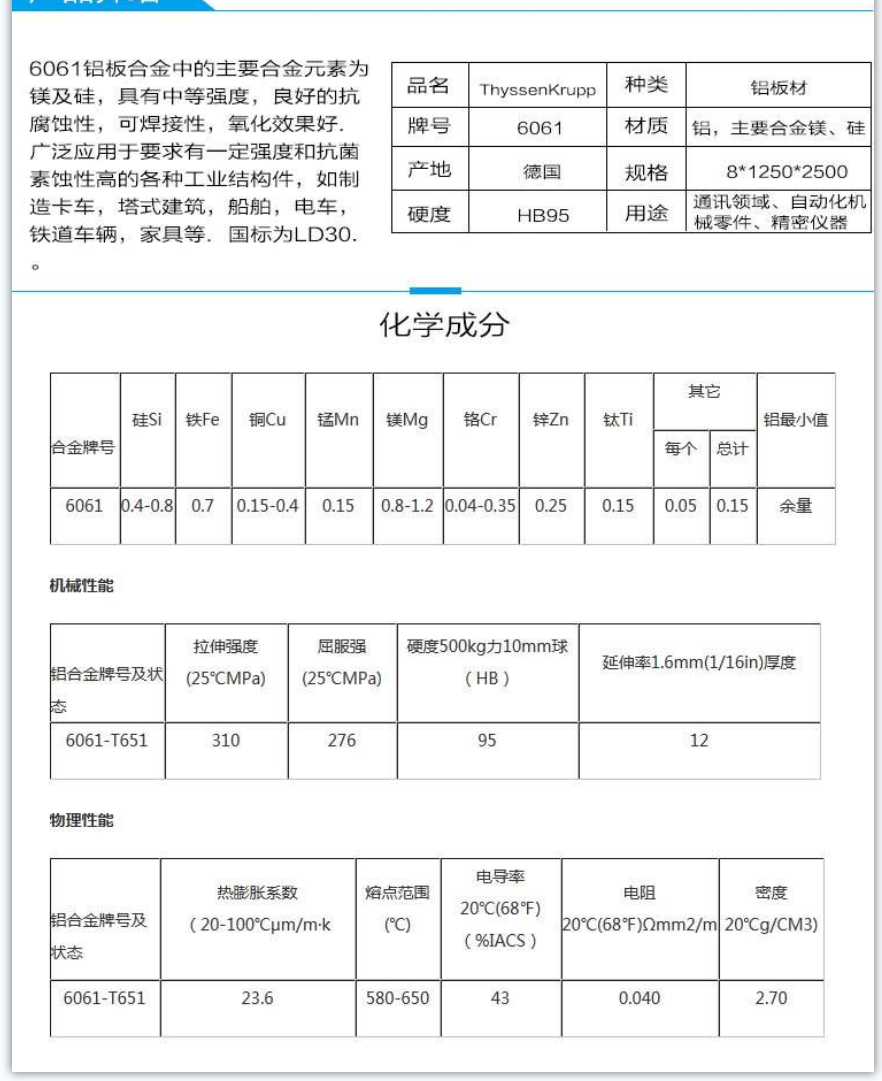

6061 Stamping Aluminum Sheet Metal is a heat-treated hardenable alloy with good formability, weldability, machinability, and moderate strength, which can maintain good operability after annealing. The main alloying elements of 6061 aluminum are Magnesium and silicon, and form the Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the bad effects of iron; sometimes a small amount of copper or zinc is added to improve the strength of the Aluminum Stamping without significantly reducing its corrosion resistance; there is also a small amount of conductive material. copper to offset the adverse effects of titanium and iron on electrical conductivity; zirconium or titanium can refine grains and control recrystallization; in order to improve machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial aging hardening function.

Nine main points of aluminum alloy stamping

We are Aluminum Stamping Companiny in China,Aluminum alloy has the characteristics of light weight, good heat dissipation, easy processing, and excellent corrosion resistance, so aluminum alloy products are widely used. The shells of many products are made of aluminum alloys, and most of the aluminum alloy shells are obtained by secondary processing of aluminum alloy sheets. In mass production, the processing of aluminum alloy shells is mainly based on stamping. During stamping production, the aluminum alloy shell is particularly prone to be crushed and scratched. Therefore, in the process of mold making and stamping production of Aluminum Metal Stamping, the following nine points should be paid attention to:

1-The Aluminum Sheet Metal Stamping material is soft, in order to prevent the deformation and displacement of the aluminum alloy during the stamping process. Precise positioning must be set on the stamping die, and the positioning device needs to have a smooth surface without water chestnuts. This can effectively reduce the defects caused by the stamping of the aluminum alloy shell.

2-Reasonably design the mold gap to prevent the Custom Aluminum Stamping from bulging and slumping.

3-When designing the structure of the Stamping Aluminum Parts, try to avoid deep sinking holes, because most of the post-processing of the aluminum alloy shell requires anodizing, and the deep sinking holes are easy to hide acid during anodization.

4-All the edges of the mold should be cut with slow-moving wires, because the edges of the molds cut by the fast and medium-moving wires are not flat, and burrs and dog teeth are prone to occur at the edges of the aluminum alloy shell during stamping.

5-When the Aluminum Stamping Parts is stamped, the aluminum alloy sheet needs to be pasted with a PE film. PE film can effectively reduce scratches and crush injuries.

6-In the Aluminum Metal Stamping production process, it is necessary to keep the mold, stamping platform, and transfer blister tray clean and free of impurities.

7-Aluminum Stamping Parts is a good conductor of heat, which is easy to conduct heat and generate heat. Therefore, it is necessary to frequently apply drawing oil on the material and mold to cool down during stamping, which can also play a lubricating role.

8-During production, if the aluminum alloy casing has too large burrs or collapsed edges, it is necessary to contact the mold department as soon as possible to repair the mold before production.

9-When the aluminum alloy shell is stamped, the operator should tear off the PE film every 20-30 pieces to check whether the aluminum alloy shell has bad stamping phenomena, such as: mold printing, crushing, scratching, bulging, slump, curling .

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !