1.Raw Material: Aluminum Alloy (model No. AL6005-T5)

2.Surface Treatment: Completely anodized with 15μm anodizing thickness

Features of anodized electrophoretic aluminum alloy:

(1)The oxide film exceeds 15μm

(2)Oxidized grit No. 100

(3)Frosted and meticulous, no mechanical traces

(4)Not easy to touch scratches, no grit

(5)Super wear resistance, weather resistance and corrosion resistance

What are the advantages of solar aluminum alloy photovoltaic brackets?

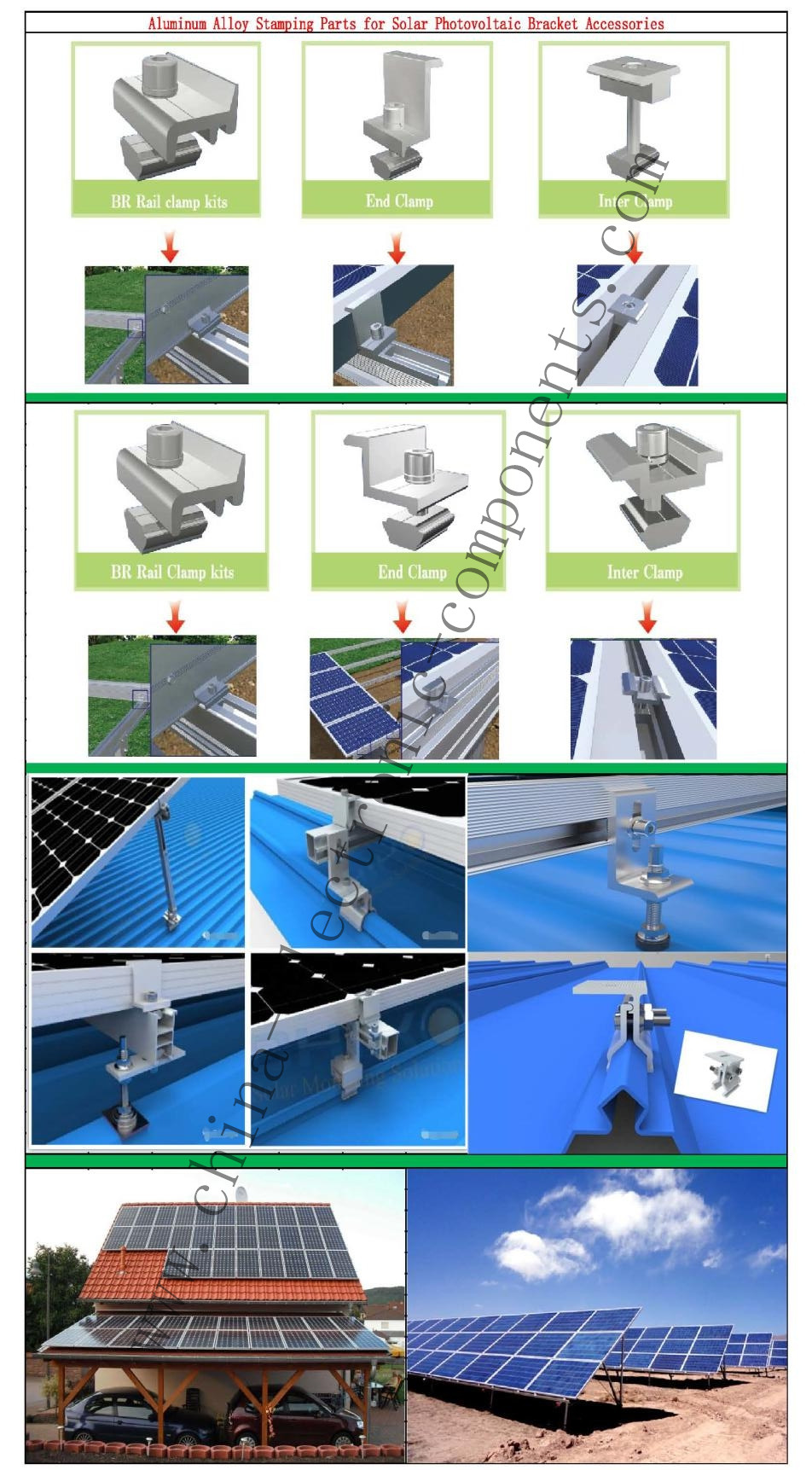

Photovoltaic industry is a rising industry based on semiconductor technology and new energy demand, and it is the commanding height of global advanced industry competition in the future. The Aluminum Clamp Hook for Roof Photovoltaic Support is one of the key components of the photovoltaic power station. As the support system of the Aluminum Photovoltaic Bracket Accessories, it is an indispensable part of the photovoltaic industry and a reliable guarantee to maximize the utilization of photovoltaic energy! Photovoltaic brackets are usually divided into ordinary steel photovoltaic brackets and Aluminum Accessories for Solar Mounting according to their materials.

What are the advantages of solar aluminum alloy photovoltaic brackets?

①. Resistance to natural corrosion: Aluminum placed in the air can form a dense aluminum oxide protective layer on the surface, which can prevent further oxidation of aluminum.

②. Anti-galvanic corrosion: When the steel bracket is in contact with the aluminum photovoltaic panel frame, the aluminum photovoltaic panel frame is prone to galvanic corrosion, while the aluminum bracket avoids this phenomenon.

③. Balance voltage: Aluminum Alloy Waterproof Solar Rail has excellent electrical conductivity, so it can better conduct weak currents generated by various reasons in the photovoltaic support system.

④.Easy to form: Aluminum profile products with different cross-sectional shapes can be easily obtained by extrusion process using different dies.

⑤.Easy processing: Aluminum Solar Panel End Clamps for PV Mounting System can be easily processed into the required specifications by sawing, drilling, punching, folding and other processes, and the energy consumption of the processing process of Aluminum Mounting Brackets is also much lower than that of steel.

⑥Low temperature resistance: ordinary steel, especially the welding area, is fragile and brittle in low temperature environment, while the strength of zinc-aluminum-magnesium material increases instead.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !