1-Products Name: Metal Steel Screw Hardware Fasteners

2-Raw Material:

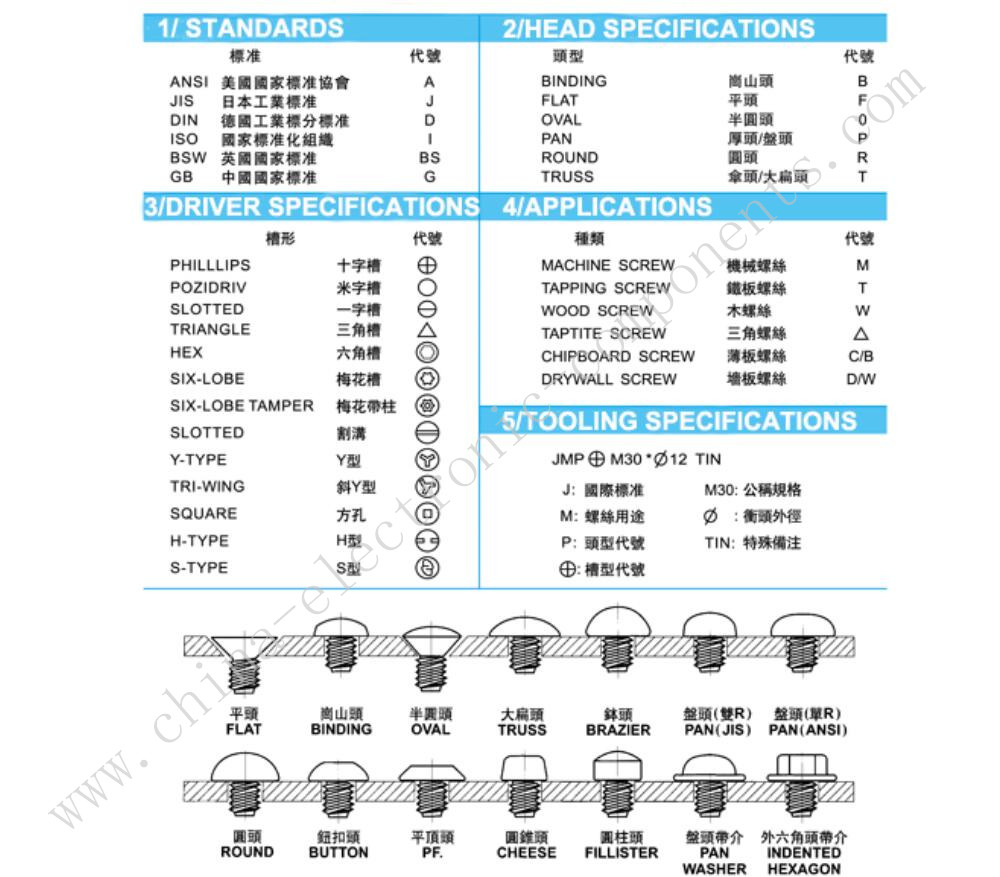

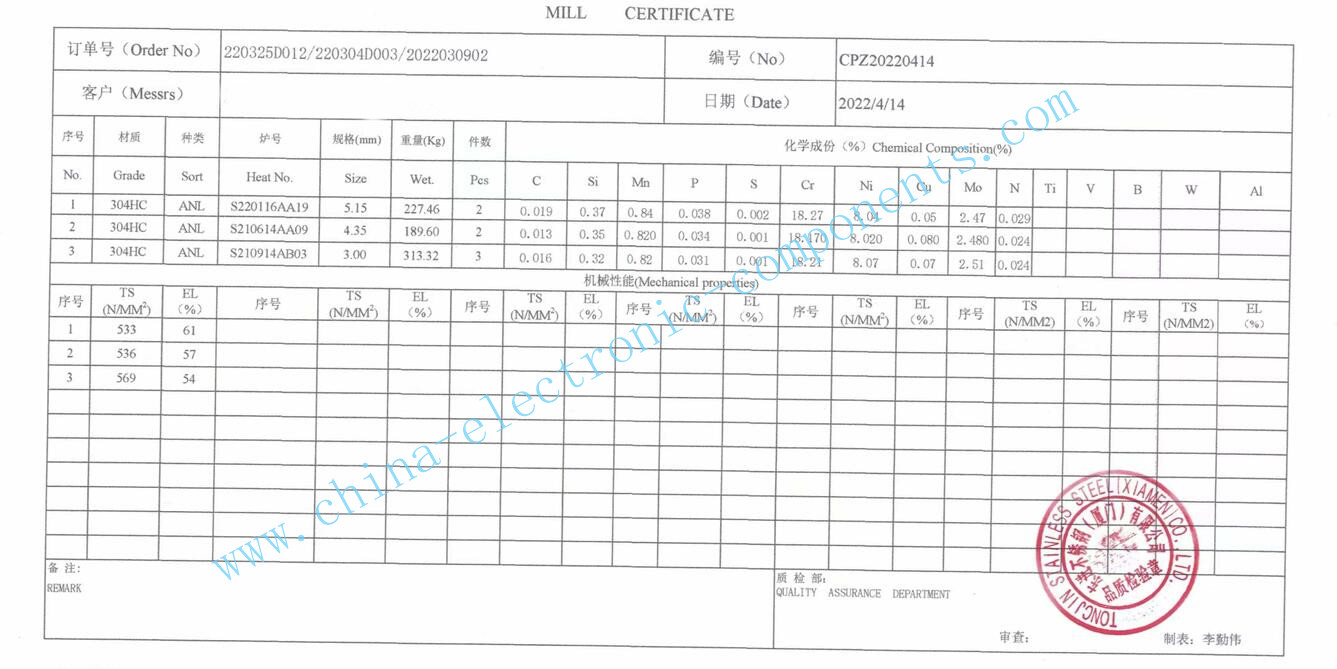

(1)Metal Screw: Carbon Steel (hot rolled steel wire ML08AL and cold rolled steel plate SPCC), Stainless Steel (302,304,316 models),Aluminum Alloy,Copper,Brass,etc,OEM accepted;

(2)Terminal Block: Carbon Steel, Copper,Brass,OEM accepted;

3-Metal Screw Size:

(1)M3/M3.5/M4/M5/M6/M7/M8/M10/M12/M14/M16/M18/M20,etc,OEM accepted

(2)British standard (BSW), German standard (DIN), German standard (DIN), Chemical industry (HG), Machinery (JB) and other standard or non-standard fasteners.

4-Surface Treatment:

(1)Electroplating Environmentally Friendly Zinc (galvanized): White Zinc, Color Zinc, Blue Zinc, Black Zinc;

(2)Other Plating: Nickel,Chrome,Lat,Pot Black,Dacromet,Copper,Tin,Silver, etc.

5-Plating Thickness:

(1)Normal economic plating thickness 4-12μm

(2)Hot-dip galvanizing thickness 37-54μm

(3)According to customer requirements,OEM accepted;

6-Salt Spray Test(NSS standard,sodium chloride concentration 5% & PH6.5-7.2):

Usually 48-96 hours, according to customer requirements, salt spray test is related to plating thickness

7-Free Samples:10-50pcs Stainless Steel Screws are allowed

8-Lead Time:7-15days(including the tooling/die and Stainless Steel Fastener samples)

9-Production Capacity:50,000,000 pcs/month

10-Products Packing:Inner plastic bag/box,Outer carton/pallet

11-Payment Item:T/T,L/C by USD/EUR/RMB

12-Quality Standard:ISO9000,IATF16949,RoHS,REACH

13-Terminal Application:Relay,Contactor,Switch,Thermostat,Circuit Breaker,Energy Meter,GAS Meters,other High/Low-voltage electrical appliances.

Stainless Steel Screws usually refer to steel screws that are resistant to corrosion by air, water, acids, alkali salts or other media. 304# Stainless steel screws are generally not easy to rust and durable, and can be used in environmental protection equipment, medical equipment, communication equipment and other fields.The raw materials of M6/M8/Hex Screws are mainly austenite 302, 304, 316 and "low nickel" 201,etc.Stainless Steel Screws mainly used for: environmental protection equipment, medical equipment,communication equipment,power facilities,electronic products, instrumentation,food machinery,petrochemical,ship assembly,pump valve pipeline,building curtain wall,open air,sports facilities,outdoor decoration, etc.

Selection principle of stainless steel screws:

1. Requirements for stainless steel screw materials in terms of mechanical properties, especially strength;

2. The requirements of working conditions on the corrosion resistance of Stainless Steel Fastener materials;

3. The requirements of the working temperature on the heat resistance (high temperature strength, oxidation resistance) of the Metal Fastener material;

4. Requirements for Screw Thread material processing performance in terms of production technology;

5. Other aspects, such as Metal Screws weight, price, procurement and many other factors should be considered.

Analysis of the reasons for the fracture of stainless steel screws

Sometimes, the metal iron screws are often seen broken, and sometimes, the stainless steel screws are also seen broken. But generally speaking, stainless steel screws rarely break. Because the stainless steel screw wire itself is relatively hard. But under certain circumstances, stainless steel screws can still break. So what are the main reasons for stainless steel screws to break?

The reasons for the fracture of stainless steel screws are as follows:

1. The quality of raw materials used for stainless steel screws is poor, and the quality of stainless steel screws is not good. There are many impurities, impure, resulting in insufficient hardness of stainless steel screws.

2. The production process of stainless steel screws. For example, stainless steel screws with eccentric head and eccentricity, and the Q value is too deep and the R position design is too small during the down punching operation during production.

3. The customer uses too much force when using stainless steel screws. Generally, you do a torque test to see how much the minimum breaking force is, and then adjust the torque.

Of course, stainless steel screws must be broken for more than three reasons. But the above three reasons are the main reasons for the fracture of stainless steel screws. When the stainless steel screw is found to be broken, it can be checked step by step. Find out what's causing it.

Why do stainless steel screws lock up?

We often experience lockup when assembling stainless steel bolts and stainless steel nuts. What is deadlock? Locking, also known as locking, refers to the phenomenon that the bolt and the nut are locked during the tightening process, which generally occurs between the stainless steel bolt and the stainless steel nut, so it is also called stainless steel screw locking or stainless steel screw locking.

For the locking phenomenon of stainless steel screws, how to avoid the locking phenomenon?

1. Keep the central axis of the Stainless Steel Screws and nut perpendicular to the locked surface, and reduce the inclination angle of the central axis of the screw and nut.

2. Use a torque wrench or barrel wrench as much as possible, avoid excessive force, and control the torque within the safe stock torque range.

3. Try not to use an electric wrench, use a manual wrench to slow down the locking speed, keep the threads clean, reduce heat energy, and thus reduce adhesion.

4. Choose Threaded Fastener screws and nuts of different materials to use together to avoid adhesion of the same material.

5. Choose anti-lock products Stainless Steel Fastener or use anti-lock lubricants to reduce friction and avoid locking.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !