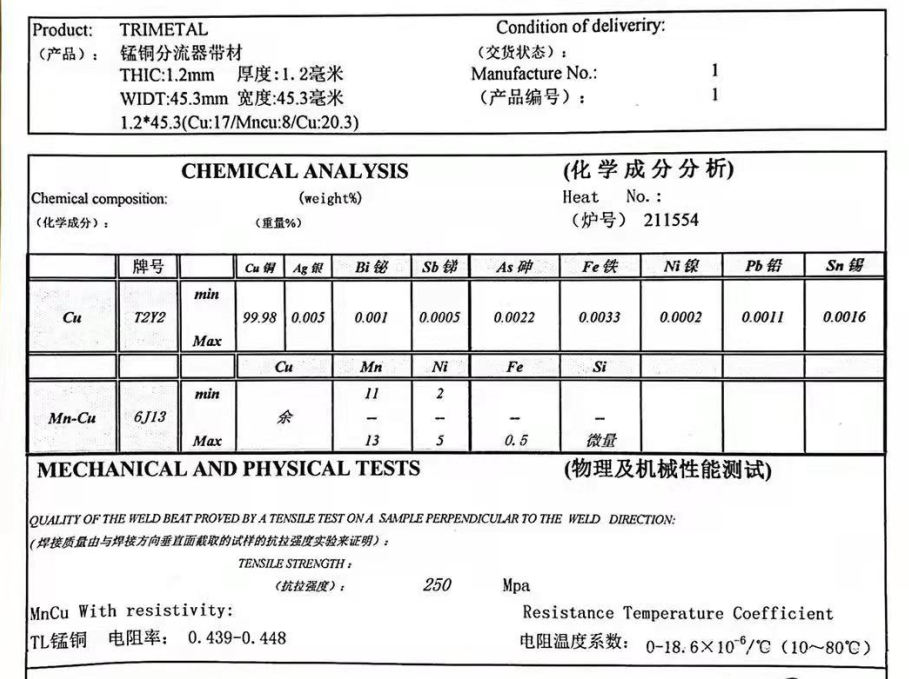

2-Material: T2Y2 Pure Copper+Manganese Copper

3-Resistance value tolerance: ± 5%

4-Process: EBW(Electron beam welding),Stamping

5-Aging: 10 hours under 120 deg

6-Power loss: <50 milli watt

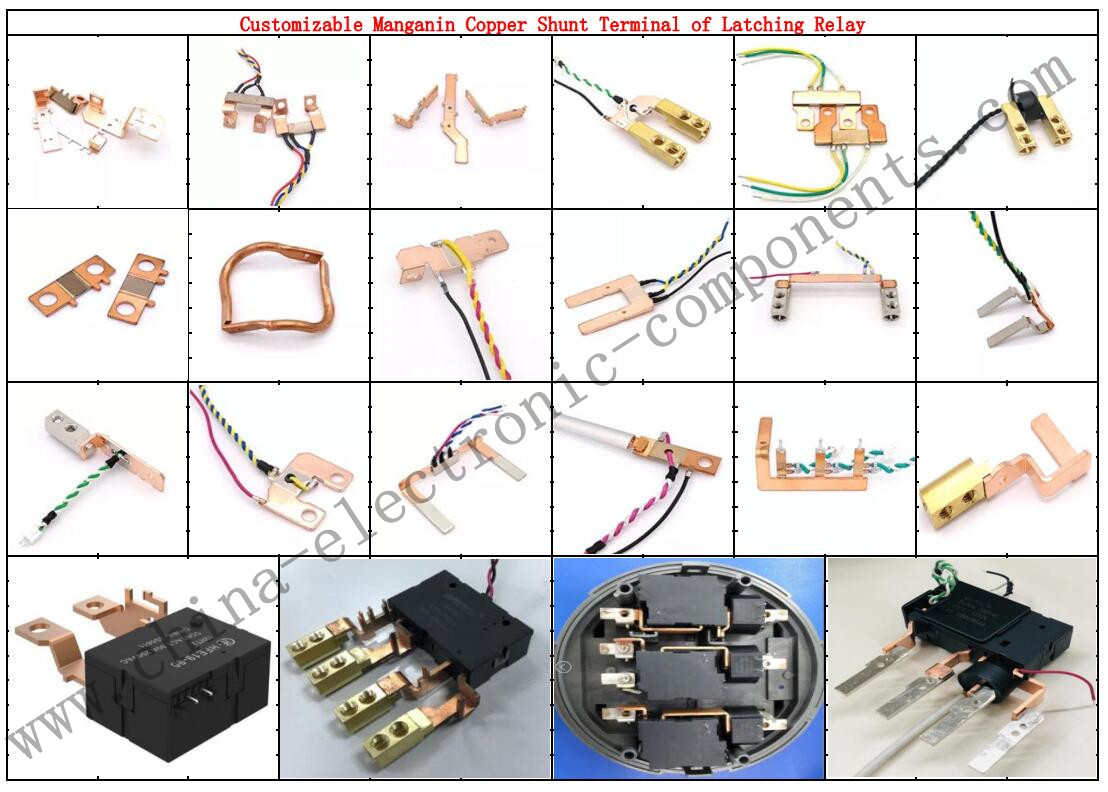

7-Termination: Integrated lead wires are available

8-Application: Work in all kinds of electrical meter as power measurer,like Prepayment Energy Meter,AMR System,Automatic Control System,Compound Switch etc.

9-Customized designs are available against customer's Latching Relay Manganin Shunt drawings/samples.

Shunt Terminal main features:

1-Extremely Good Long Term Stability

2-EBW from Cu-MANGANIN-Cu

3-Negligible Power Loss Due to Lowest TCR-Value

4-low heat dissipation, low temperature,low resistance value

5-Customized Optional to Realize Economic Solutions

Manganin Shunt Terminal is a precision resistance element for making high-grade metering voltage, current, bridge, potentiometer and other instruments, and is more suitable for making standard resistors for benchmarks. The manganese-copper shunt (Static Copper Plate with Manganese sampling resistor) of the electric energy meter is widely used in various digital electric energy meters as an electric quantity measuring element. It is made of Copper Manganese precision resistance alloy material.

Shunt Terminal for Magnetic Latching Relay(BMn3-12 Cu-Mn-Ni cupronickel)belongs to the precise resistance alloy material of NiCrMnCu Series.Xiamen China Apollo company produces Electrical Meter Shunt with high quality manganic, so our products Resistor Shunts have reliable performance and accurate measurement.We can also design for customers according to their different requirements of Manganin Copper Shunt.

Characteristics of Electron Beam Welding of Manganese Copper Shunts of Magnetic Latching Relays

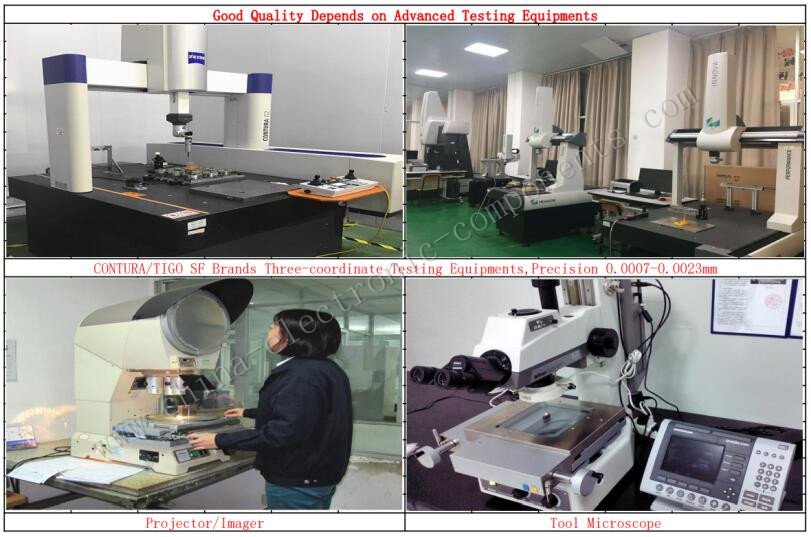

1-The electron beam penetration ability is strong, the power density is extremely high, the aspect ratio of the weld seam is large, which can reach 50:1, and the large thickness material can be formed at one time, and the maximum welding thickness can reach 300mm.

2-The welding accessibility of Copper Manganin Shunt is good, the welding speed is fast, generally above 1m/min, the heat affected zone is small, the welding deformation is small, and the welding structure precision is high.

3-The electron beam energy can be adjusted, and the thickness of the metal Electric Current Measure Manganin Shunt to be welded can be as thin as 0.05mm to as thick as 300mm, without grooves, and one-time welding, which cannot be achieved by other welding methods.

4-The range of materials Micro Ohm Manganin Welding Shunt Resistor that can be welded by electron beam is large, and it is especially suitable for the welding of active metals, refractory metals and workpieces with high quality requirements.

5-It can be precisely controlled, with good repeatability and stability (of course, this is closely related to the performance of the equipment).

6- Since it is carried out in a vacuum, the weld quality of Magnetic Shunt Customized can be improved.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !