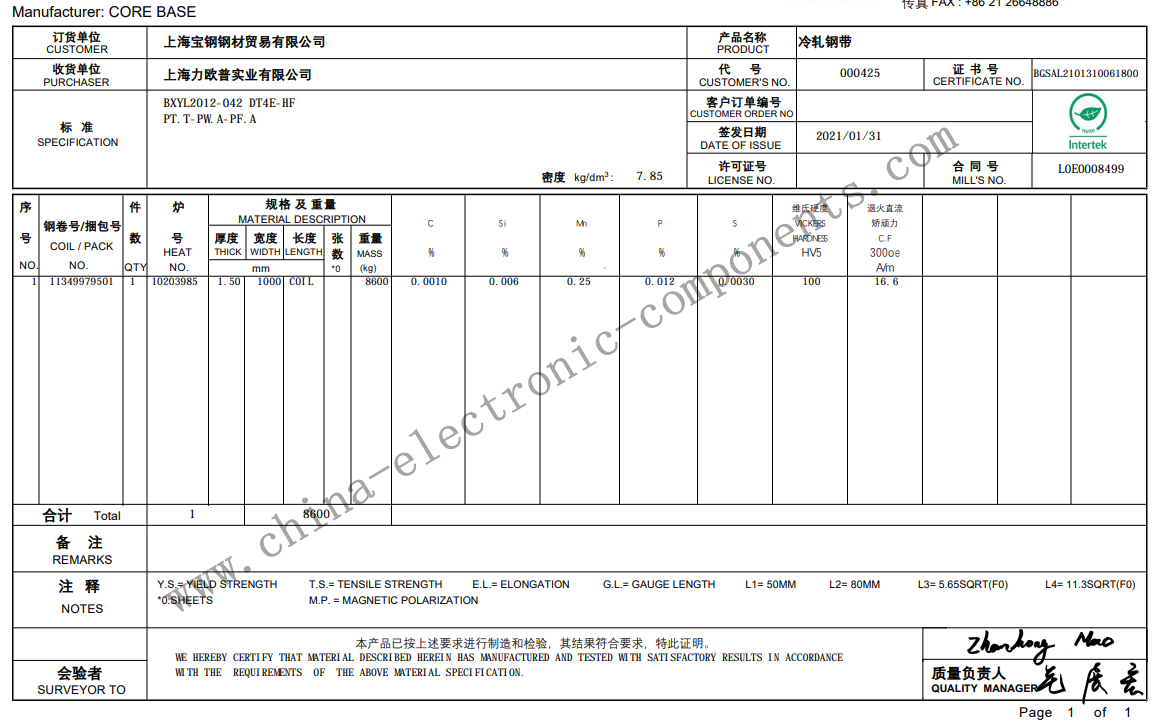

1-Base Material: Electrician pure iron cold rolled steel (China model No DT4E)

2-Surface Plating:

(1)Annealing with high temperature to remove coercive force;

(2)No plated or as require Copper-plated,Copper primer and nickel plating,etc.

3-OEM/ODM:Accepted,need your drawing

4-Free Samples:10-50pcs is allowed

5-Lead Time:Samples 10-20days,Orders 7-10days(including the tooling/die production)

6-Application:Industrial Relay,Power Relay,High Power Metering Relay,Automotive Relay,Signal Relay,new energy HVDC Relay,new energy HVAC Relay

The use of electrician pure iron:

1.Electrician Pure Iron various types of Relay Cores,Armature,Yokes in electrical appliances and telecommunications.

2. Coil Soft Iron used for turning and focusing magnets of high-energy accelerators, electro-acoustics, solenoid valves, electromagnet cores of magnetic separation equipment, etc.

3. Electromagnet Pure Iron used for high-resolution magnet pole heads on analytical instruments, electromagnetic separators and geophones in geological instruments, focusing magnets and scanning electromagnetic lenses for electron microscopes, aircraft automatic control components, pole heads for magnetizers, etc.

4. The iron core and shell used for DC motors.

5. Electrical appliances or magnetic parts used in automobiles and lathes.

6. Shielding materials used for all kinds of magnetic shielding covers or shielding boxes that require high shielding equipment.

The yoke is an optional component on the electromagnet, which is used to enhance the attraction force of the electromagnetic coil, enclose the magnetic field lines generated by the electromagnetic coil inside, and improve the efficiency of the electromagnet.

The yoke is one of the parts on the electromagnet. The armature of the general electromagnetic servo mechanism (including the relay), that is, the moving iron core attracted by the electromagnet, is located in the center of the coil, which cannot make full use of the magnetic energy of the electromagnetic coil. When the yoke (that is, a static iron core) is added, the yoke It forms a closed magnetic circuit with the armature, which seals the magnetic lines of force generated by the electromagnetic coil inside, so that the magnetic energy is fully utilized, and the efficiency of the electromagnet is maximized.

What’s the latest technological design of the armature?

The armature of the relay designed by us aims to solve the technical problem that the flatness of the armature in the prior art cannot meet the requirements of use.

To achieve the above purpose, the relay armature we designed includes an armature body. The upper end of the armature body is provided with a hook. Both sides of the armature body are provided with buckle grooves. The front of the armature body is provided with a first contact piece and a second contact piece. , The second contact piece is arranged below the first contact piece, the first contact piece is arranged below the hook, the armature body is provided with a plurality of fixing holes penetrating the front and rear ends of the armature body, and each fixing hole is arranged in the first contact Between the sheet and the second contact sheet, the front and back sides of the armature body are provided with a plurality of interlaced embossments.

We are a new type of relay armature with one of the following technical effects: when in use, the armature is connected to the knife edge of the yoke of the relay through the buckle slot, the yoke of the relay and the first contact piece are attached to each other, and the relay is pulled The spring is connected to the hook. After the electromagnetic force disappears, the tension spring of the relay pulls the hook to reset the armature body. The fixed hole is used to install the movable reed of the relay. The movable reed of the relay is attached to the reverse side of the armature body. , The second contact piece arranged on the front side of the armature body and the iron core of the relay are attached to each other. Because the front and back sides of the armature body are provided with interlaced embossing, the armature body and the movable reed and the first contact piece are less And the contact area of the second contact piece improves the flatness of the armature body, thereby improving the stability performance of the relay.

Contact Information:

Mr.Terry Young (Sales Manager&Technology Engineer)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor&Breaker ect Riveting&Welding solutions !