What’s the latest technological design of the armature?

The armature of the relay designed by us aims to solve the technical problem that the flatness of the armature in the prior art cannot meet the requirements of use.

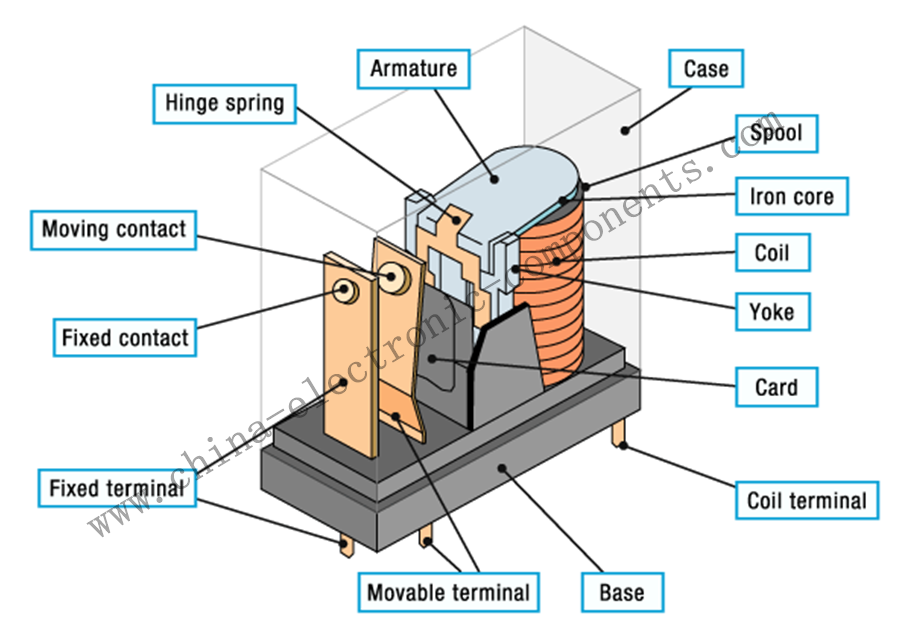

To achieve the above purpose, the relay armature we designed includes an armature body. The upper end of the armature body is provided with a hook. Both sides of the armature body are provided with buckle grooves. The front of the armature body is provided with a first contact piece and a second contact piece. , The second contact piece is arranged below the first contact piece, the first contact piece is arranged below the hook, the armature body is provided with a plurality of fixing holes penetrating the front and rear ends of the armature body, and each fixing hole is arranged in the first contact Between the sheet and the second contact sheet, the front and back sides of the armature body are provided with a plurality of interlaced embossments.

We are a new type of relay armature with one of the following technical effects: when in use, the armature is connected to the knife edge of the yoke of the relay through the buckle slot, the yoke of the relay and the first contact piece are attached to each other, and the relay is pulled The spring is connected to the hook. After the electromagnetic force disappears, the tension spring of the relay pulls the hook to reset the armature body. The fixed hole is used to install the movable reed of the relay. The movable reed of the relay is attached to the reverse side of the armature body. , The second contact piece arranged on the front side of the armature body and the iron core of the relay are attached to each other. Because the front and back sides of the armature body are provided with interlaced embossing, the armature body and the movable reed and the first contact piece are less And the contact area of the second contact piece improves the flatness of the armature body, thereby improving the stability performance of the relay.

The characteristics of electrical pure iron:

1-Good electromagnetic performance: low coercivity, high permeability, high saturation magnetic induction, stable magnetism and non-magnetic aging.

2-The smelting process of electromagnetic pure iron series adopts hot metal pretreatment, RH refining, electromagnetic stirring and other processes. The interior is dense and uniform, with low gas content and low carbon content in the finished product.

3-Good cold and hot processing performance:Electrician Pure Iron cold processing can meet the process requirements of turning, piers, punching, bending, drawing, etc., hot processing, such as re-forging and re-rolling, the sensitivity of red brittleness is small, and it can be guaranteed in a larger temperature range Processing within.

4-Good surface quality: good welding and electroplating performance.

5-High dimensional accuracy: ultra-precision cold-rolled plates can be provided, such as thick plates ≤1.5mm, and the thickness tolerance can be guaranteed ≤±0.01mm.

Reduce the coercive force or stress of electrical pure iron through high temperature annealing

Why is the coercivity value of pure iron Cold rolled steel material increased a lot after processing the finished product. The product use effect is not ideal. Is there something wrong with the material, or is there something hidden? For this reason, our company specially organizes the following information, hoping to solve problems for our friends.

①Why should pure iron be annealed?

Answer: Because cold working causes many crystal defects (dislocations, stacking faults, etc.) in pure iron, and causes internal stress, increases the difficulty of magnetic domain wall movement, increases Hc, and decreases μm value. In order to eliminate these adverse effects, electrical pure iron must be subjected to stress relief annealing or recrystallization annealing.

②What are the improvements to pure iron Cold rolled steel after annealing?

Answer: The high annealing temperature makes the crystal grains coarser and eliminates the stress of the pure iron material, which is beneficial to the magnetic permeability. Therefore, the stress-relief annealing generally adopts the highest temperature that does not cause α←→γ phase transition to avoid phase transition during cooling. Grain refinement.

③The annealing temperature and time of Electrician Pure Iron?

Answer: Yaoqiang pure iron usually adopts the recrystallization annealing process system to eliminate the cold working stress: install the furnace below 600℃, raise the temperature to 800℃ with the furnace, and then slowly heat to 830~890℃, keep the temperature for 4h, and then the temperature is no more than The cooling rate of 50℃/h is cooled to 700℃, and finally cooled to below 500℃ with the furnace. The entire annealing is performed in hydrogen or vacuum.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !