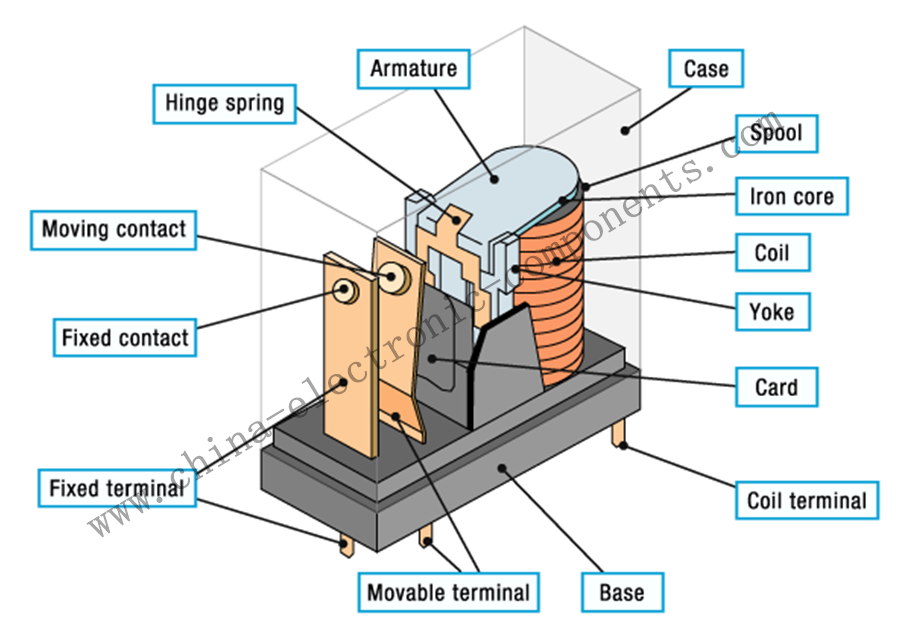

Electromagnetic relay is an electronic control device. It has a control system and a controlled system. It is usually used in automatic control circuits. It actually uses a smaller current and a lower voltage to control a larger current and a higher voltage. A kind of "automatic switch". Therefore, it plays the role of automatic adjustment, safety protection, and conversion circuit in the circuit. Usually used in automatic control circuits, when the control loop inputs the corresponding electrical signals, the electromagnetic system generates electromagnetic force, attracting the armature to close the armature and the iron core, thereby driving the contacts to be connected or disconnected, but in actual production, the relay After the armature is assembled into a relay after stamping, heat treatment, electroplating, transportation, etc., the flatness of the armature cannot meet the requirements for use, and it directly affects the contact effect between the armature and the iron core, and then affects the use of the relay.

The use of electrician pure iron:

1.Electrician Pure Iron various types of Relay Cores,Armature,Yokes in electrical appliances and telecommunications.

2. Coil Soft Iron used for turning and focusing magnets of high-energy accelerators, electro-acoustics, solenoid valves, electromagnet cores of magnetic separation equipment, etc.

3. Electromagnet Pure Iron used for high-resolution magnet pole heads on analytical instruments, electromagnetic separators and geophones in geological instruments, focusing magnets and scanning electromagnetic lenses for electron microscopes, aircraft automatic control components, pole heads for magnetizers, etc.

4. The iron core and shell used for DC motors.

5. Electrical appliances or magnetic parts used in automobiles and lathes.

6. Shielding materials used for all kinds of magnetic shielding covers or shielding boxes that require high shielding equipment.

The yoke is an optional component on the electromagnet, which is used to enhance the attraction force of the electromagnetic coil, enclose the magnetic field lines generated by the electromagnetic coil inside, and improve the efficiency of the electromagnet.

The yoke is one of the parts on the electromagnet. The armature of the general electromagnetic servo mechanism (including the relay), that is, the moving iron core attracted by the electromagnet, is located in the center of the coil, which cannot make full use of the magnetic energy of the electromagnetic coil. When the yoke (that is, a static iron core) is added, the yoke It forms a closed magnetic circuit with the armature, which seals the magnetic lines of force generated by the electromagnetic coil inside, so that the magnetic energy is fully utilized, and the efficiency of the electromagnet is maximized.

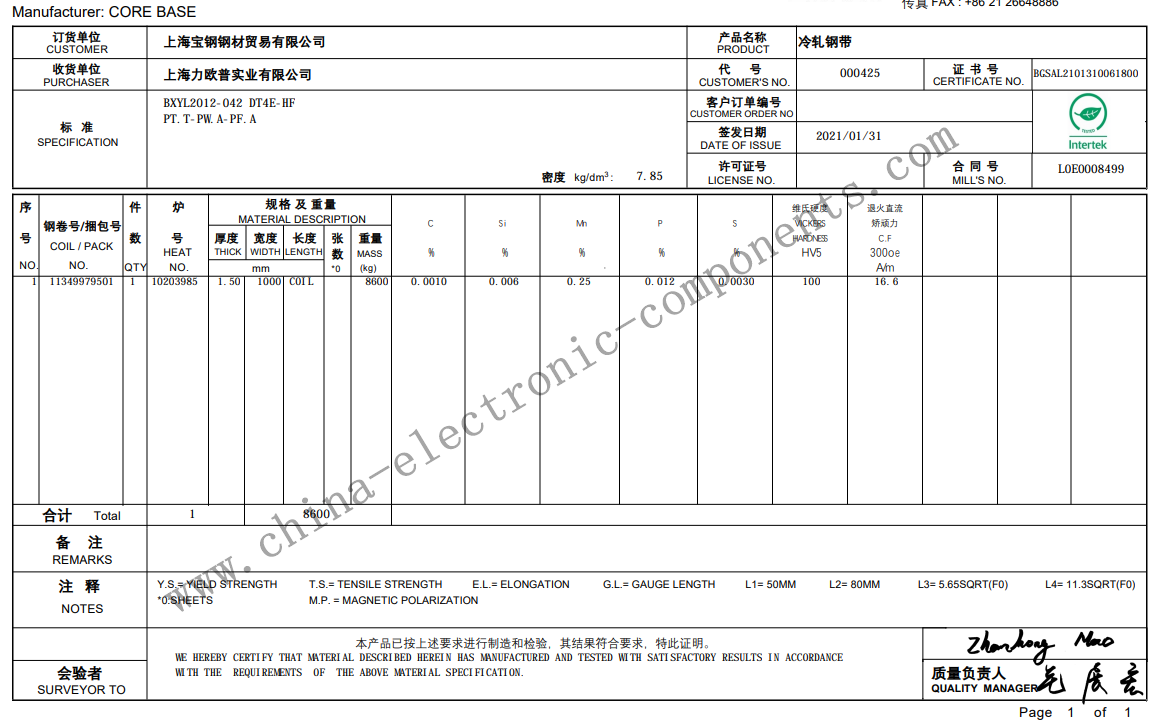

Which is better the coercive force of the relay ferromagnetic material large or small?

Coercive force of Electrician Pure Iron means that the magnetic induction intensity B does not return to zero when the external magnetic field returns to zero after the saturation magnetization of the magnetic material. Only by adding a certain magnitude of magnetic field in the opposite direction of the original magnetization field can the magnetic induction intensity return to zero. The magnetic field is called the coercive magnetic field, also known as the coercive force.

The intensity of the external magnetic field opposite to the original magnetization direction must be added to make the magnetized ferromagnetic material lose its magnetism. It is not only related to the properties of ferromagnetic substance, but also depends on the original magnetization intensity of ferromagnetic substance. When manufacturing the Electromagnet soft iron core or electromagnet of the transformer, it is necessary to choose materials with low coercivity (such as soft iron, silicon steel, etc.) to make the magnetism disappear as soon as possible after the current is cut off. When manufacturing permanent magnets, it is necessary to choose materials with high coercivity (such as AlNiCo, etc.) in order to preserve the magnetism as much as possible and prevent it from disappearing.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !