The characteristics of electrical pure iron:

1-Good electromagnetic performance: low coercivity, high permeability, high saturation magnetic induction, stable magnetism and non-magnetic aging.

2-The smelting process of electromagnetic pure iron series adopts hot metal pretreatment, RH refining, electromagnetic stirring and other processes. The interior is dense and uniform, with low gas content and low carbon content in the finished product.

3-Good cold and hot processing performance:Electrician Pure Iron cold processing can meet the process requirements of turning, piers, punching, bending, drawing, etc., hot processing, such as re-forging and re-rolling, the sensitivity of red brittleness is small, and it can be guaranteed in a larger temperature range Processing within.

4-Good surface quality: good welding and electroplating performance.

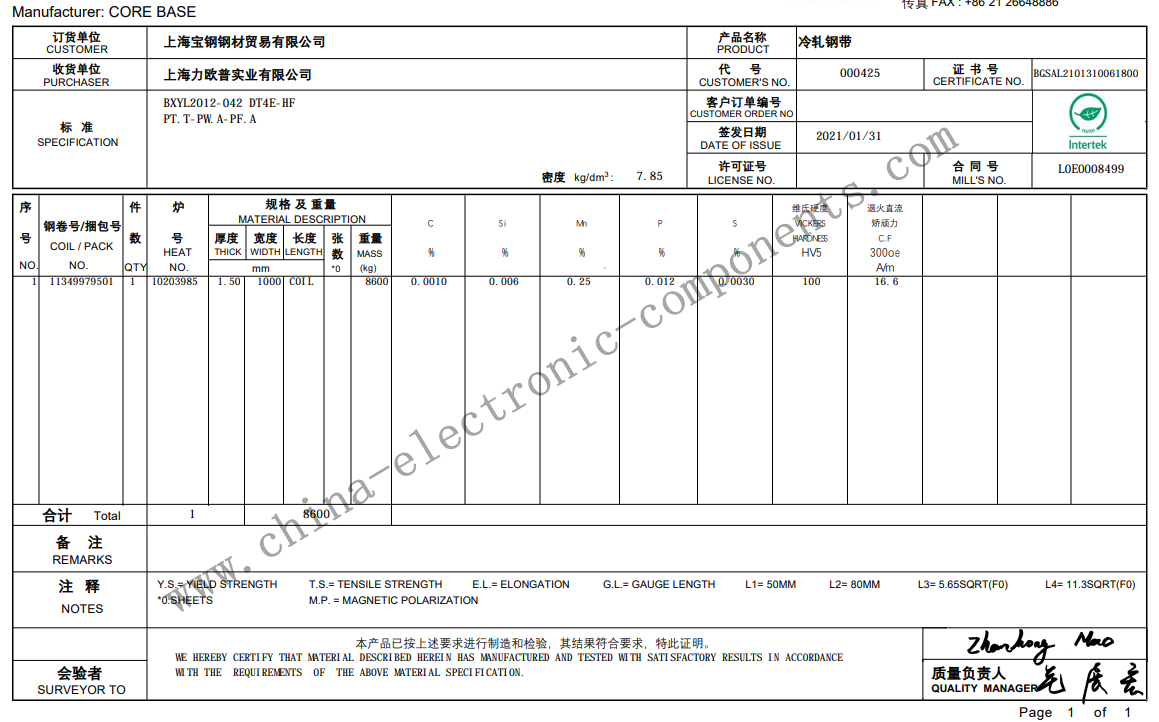

5-High dimensional accuracy: ultra-precision cold-rolled plates can be provided, such as thick plates ≤1.5mm, and the thickness tolerance can be guaranteed ≤±0.01mm.

Which is better the coercive force of the relay ferromagnetic material large or small?

Coercive force of Electrician Pure Iron means that the magnetic induction intensity B does not return to zero when the external magnetic field returns to zero after the saturation magnetization of the magnetic material. Only by adding a certain magnitude of magnetic field in the opposite direction of the original magnetization field can the magnetic induction intensity return to zero. The magnetic field is called the coercive magnetic field, also known as the coercive force.

The intensity of the external magnetic field opposite to the original magnetization direction must be added to make the magnetized ferromagnetic material lose its magnetism. It is not only related to the properties of ferromagnetic substance, but also depends on the original magnetization intensity of ferromagnetic substance. When manufacturing the Electromagnet soft iron core or electromagnet of the transformer, it is necessary to choose materials with low coercivity (such as soft iron, silicon steel, etc.) to make the magnetism disappear as soon as possible after the current is cut off. When manufacturing permanent magnets, it is necessary to choose materials with high coercivity (such as AlNiCo, etc.) in order to preserve the magnetism as much as possible and prevent it from disappearing.

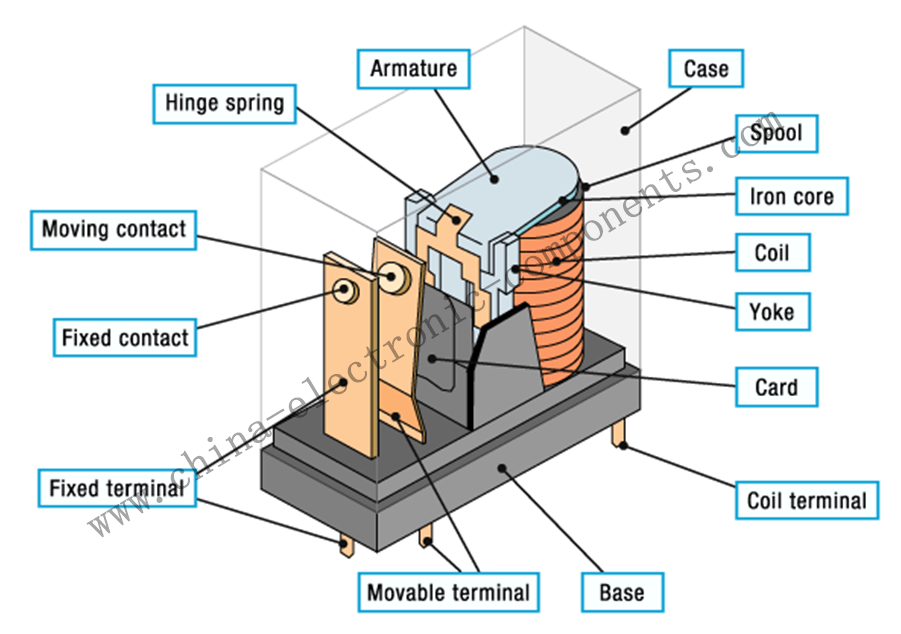

The yoke parts are made of thin materials, small dimensions and high precision requirements. After comprehensively considering the process plan of the parts processing, the production batch and other issues, it is determined to use the punching and blanking compound die plus the bending process, and the mold base and other parts are selected from the country standard. Strive to achieve streamlined mold structure, low process cost and reliable implementation to meet production needs.Design the composite mold of the part, the part is the yoke of the electromagnetic relay, the material is DT4E pure iron plate, the thickness is 2.00 mm or as customers’ requires.

The yoke is an optional component on the electromagnet, which is used to enhance the attraction force of the electromagnetic coil, enclose the magnetic field lines generated by the electromagnetic coil inside, and improve the efficiency of the electromagnet.

The yoke is one of the parts on the electromagnet. The armature of the general electromagnetic servo mechanism (including the relay), that is, the moving iron core attracted by the electromagnet, is located in the center of the coil, which cannot make full use of the magnetic energy of the electromagnetic coil. When the yoke (that is, a static iron core) is added, the yoke It forms a closed magnetic circuit with the armature, which seals the magnetic lines of force generated by the electromagnetic coil inside, so that the magnetic energy is fully utilized, and the efficiency of the electromagnet is maximized.

Contact Information:

Mr.Terry Young (Sales Manager)

Apollo Electronic Components (Xiamen) Co.,Ltd

Xiamen Apollo Stamping Welding Technology Co., Ltd

Add:225#,Jinshang Road,Huli District,Xiamen City,Fujian Province,China,361009

Tel&Fax: 0592-5765084, Mob/WhatsApp/WeChat: 0086-13859903038 ,QQ: 1260358661

Email: yfd@china-electronic-components.com

Web: www.china-electronic-components.com , www.stamping-welding.com

Since 1990,professional in Silver Contact Rivet&Core&Screw Terminal for Relay&Switch&Contactor ect Stamping&Welding solutions !